We have successfully installed the P-250AVF screen printing device (Keko Oprema d.o.o., Slovenia), which was partly funded by the Slovenian Research and Innovation Agency (Package 21, applicant Prof. Dr. Danjela Kuščer). The P-250AVF is fully automated screen printing device specifically designed for printing structures with complex geometries. It has a capability of printing on substrates such as ceramics, unfired ceramics, glass, polymers, and textiles. The device can handle sizes ranging from 50 mm to 200 mm, with a maximum thickness of approximately 200 micrometres. The printing process involves attaching the substrate to the device holder by a vacuum. The dispersion is then pressed through a mask onto the substrate using a squeegee, and the resulting pattern corresponds to the geometry of the mask pattern.

This equipment enables a computer-controlled printing process with an automatic optical alignment system. The mechanical positioning repeatability is up to ±5 μm, ensuring precise and accurate printing. The machine features a lifting print head with a servo motor drive, as well as a double squeegee head that allows for automatic and controlled adjustment of the squeegee parameters including height up to 50 mm, force ranging from 0 to 250 N, and speed from 0 to 350 mm/s. The double vacuum system integrated into the vacuum table enables the printing of viafill. The machine has been designed with safety and health standards, ensuring a safe working environment for operators.

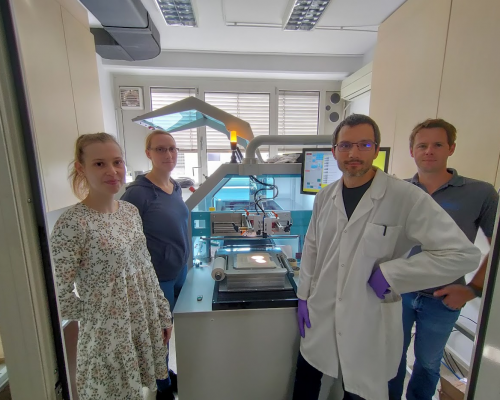

Photo by: S. Drnovšek, D. Kuščer, K. Makarovič